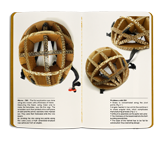

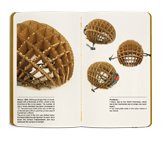

Above: D01: The first exploration was done using AAc board, with a thickness of 14mm.

Measuring the head, using metal wire to make the templates, was the first step. The templates were then plotted onto a stiff piece of card and the joinery sections were marked out. They were then translated onto the AAc board.

By pivoting the ribs along two points along the x and y axis, a multi- directional structure was achieved from all angles.

Problems with D01

• Stress is concentrated along the pivot points.

• Angles needed to be cut into the cardboard to create angular slots, which complicates manufacturing process.

• Difficult to assemble as the parts look alike.

• The thickness of the board restricts the form building possibilities.

• The base of the helmet has to be flat for construction thus restricting design.